In today’s world precision and quick delivery times help industries to stay ahead in the competition. In order to get a good reputed in the market the industries need to stay committed and provide high-quality products to the end users. Most industries are going from manual to automatic and this is where the CNC precision turning comes in handy. This is one method which is known to have a lot of benefits for the producer as well as the end user on a whole. Using this method of CNC precision turning and cutting will result in less wastage and efficient output which is the need of the hour.

|

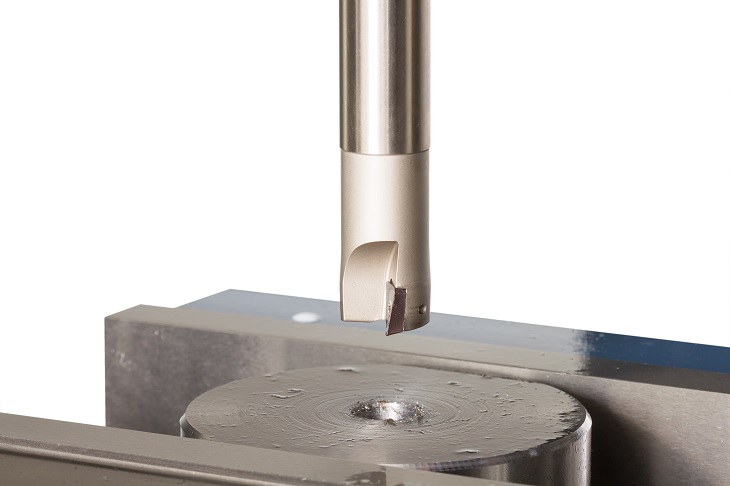

| CNC Precision Turning |

Some Tops Benefits of CNC Precision Turning Method Which You Can Be Sure of Are as Follows:

1.) Higher Accuracy:

The cost of manufacturing different component will reduce drastically with this precision turning method because cutting and shaping tiny or big components will become very easy and quick. As this method is completely computer controlled you can be sure of perfect final output. There will be very minimal risk of any errors and this is the best part about CNC. You can also be sure of tight tolerance levels once this method is used and incorporated in your production. This method will also assure you of high-quality reliable products after the turning and cutting are done.

2.) Reduction in Wastage:

Engineering components require very precise designing and high tolerance levels. Thus, incorporating CNC precision turning method to cut and make the components will be essential for you. There will be a major reduction in the wastage because you will not only know the exact design but you will also be doing all the cutting work with the help of computerized technology. Once the team you have has gained experience on this you can be sure of the fact that they will all manage it well. This will ultimately lead to timely delivery and reduced wastage on a whole.

3.) Increased Production:

All the machines which help or are used in CNC precision turning are technically advanced. These machines surpass human abilities and therefore can guarantee correct and increased production of all the material required. As they can work at a faster pace things get easier and production can get very simplified. You will thus be able to commit high quantity to the buyer and further make sure that you also deliver the same to them at the right time.

4.) Automated Assembly Features:

Every machine you can use on CNC precision turning and cutting are engineered with automated assembly features. This will in all eliminate the need for human assembly. As there will be no need for any manual assembly you can be sure of zero errors. No human hands will be required to assemble the many different components which are cut using the CNC precision turning method and as a result you can be sure that the product manufactured will be full proof and without any error.

|

| CNC Turning |

The demand for CNC precision turning method to design and cut different components has been rising and therefore incorporating the same in your business is essential. You can have a specialized team that understand the skills and then manages the precision turning and cutting for various projects. It is only by this you will be able to sustain in the competitive market and make sure of the fact that you build customer loyalty and understanding amongst a majority of the people.

Though CNC precision turning was in trend there have now been too many changes which are important to know and understand for better efficiency.

0 comments :

Post a Comment